Flow Control Chutes

Dust Control Technologies, Inc. has always been a big proponent of the use of Flow Control Chutes as a means of preventing wear, noise, degradation of material and dust at transfer points, where the turbulence created by a normal chute enhances the already present dust and wear problems, instead of steadily directing the flowing the material in a much calmer, smoother manner conducive to proper material handling, dust control and wear prevention. DCT believes that the WEBA Designed Chutes are the very best engineered chutes in the world. With superior engineering and computer flow modeling WEBA can truly accomplish amazing things for your material handling process!

Types of Flow Control Chutes

There are two main types of Flow Control Chutes, the Cascade Style Chute unit which utilizes a “Material on Material” approach along with dynamic flow engineering to vastly extend the life of a transfer chute, by using custom engineered “steps” or “shelves” in the chute it allows the material to build up on these “steps” and thus the flowing material mainly wears on the built up material and not directly on the wear components of the Flow Control Cute itself.

The Super Tube Chute type of Flow Control Chute is a more conventional style of Lined Chute, in that it utilizes hardened wear liners within the chute to absorb the impact and abrasion from the flowing material. That is where this type of Flow Control Chute steps away from conventional chutes, and with the use of curved tube custom flow design that reduces the free falling impact and turbulence that tears the wear liners out of a conventional chute with normal daily use. These chutes are specifically engineered to each individual application, considering, belt speed, material type, falling flow as well as many, many other factors to produce the smoothest material transfer transition possible with the technology available today.

Combining with Fog Based Suppression

With the addition of Fog Based Fugitive Dust Suppression, the fugitive dust at any problem transfer point can virtually be eliminated and the maintenance costs of constantly replacing wear liners in current chutes greatly reduced.

Not all transfers chutes require this sophisticated of an upgrade, if material wear on your current transfer chute is not the issue and reduction of fugitive dust is, please take a look at DCT’s, Fog and Water Based, Dust Suppression Systems Page to see what they can do to provide a solution to your Fugitive Dust problems.

And if wear problems are an issue for you then please see our pages on our Industrial Coatings and Wear Products page to view our line of products, to either replace or repair problem wear areas.

Flow Control Chutes Gallery

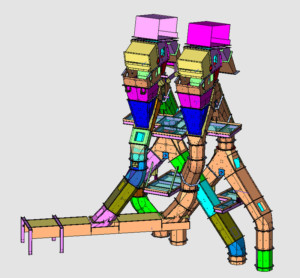

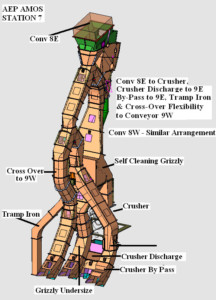

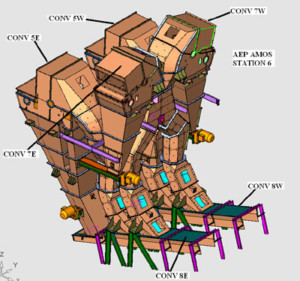

- Design Model 1

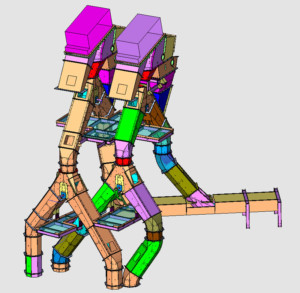

- Design Model 2

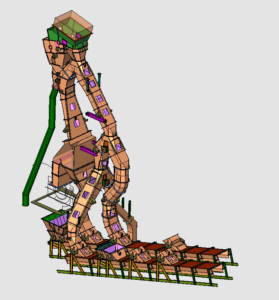

- Design Model 3

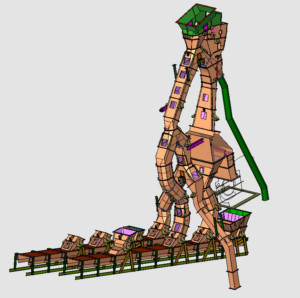

- Design Model 4

- Design Model 5

- Design Model 6

- Flow Control Chute

- Flow Control Chute for PRB Coal

- Weba In Copper Bottom

- Weba In Copper Bottom

- Weba In Copper Bottom