Wind Fencing

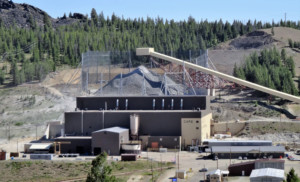

DCT has been a distributor with WeatherSolve Structures, Inc. since 1998. We design, sell and install the Wind Fences. Wind fencing controls windblown fugitive dust and stockpile degradation for the mining and bulk material handling industries.

Each wind fence system is custom engineered, designed, built and installed for your specific geographical area and wind patterns. This maximizes their effectiveness for your exact situation and control requirements. Whether you are trying to prevent product loss, airborne dust pollution, protecting process transfer points or virtually any other wind driven problems. Right down to protecting people, crops or processes like welding and cutting from exposure to the wind driven elements.

Why use Wind Fences?

Unlike other forms of fugitive dust prevention tools in the industry, wind fences provide reliable control of dust and product loss without all of the operational and maintenance costs. Once installed they require no power, compressed air, water, daily maintenance and, in most cases, no spare parts to keep the Wind Fence operating 24/7 every day, 365 days a year. Wind fences just work all day, every day.

The support structures are custom designed to withstand the forces of wind for your specific area. The Wind fabric is designed to "break away" on the bottom and sides, while still remaining attached at the top during an extraordinary wind event. This prevents, in most cases, the fabric from being damaged due to higher than specified wind speeds. The exact wind shear speed that it takes to break the wind fabric loose from the frame is custom tailored to each end users requirements and geographical location and is designed to protect the entire Wind Fence system from critical support failure. After the weather event has passed the wind fabric can simply be reattached to the support structure and the Wind Fence can be put right back into service. By being designed to release part of the fabric during a high wind event the fabric is better protected from ripping and tearing as the wind exceeds its maximum designed operational limits.

Other Wind Control Options

In addition, DCT has developed a temporary welding screen as well as a screen that can be stretched between the receiver hitches of two pickup trucks for job-site wind control. These systems are easy to setup and transport from site to site and have proven invaluable for keeping personnel and processes sheltered from the wind while working in the field.

These Wind Fence systems have been proven to work very well in conjunction with DCT Dry Fog based systems, for the drastic reduction or elimination of fugitive dust in conveyor/process transfer points, loading/unloading areas as well as many other process and operating areas.

Please see our section on DCT Dry Fog and Water Spray systems for more information on these types of applications and how they can fix your Fugitive Dust Issues.

Wind Fencing Gallery

- Building Protection

- Complete Stockpile Enclosure

- Facility Protection

- Floating Wind Fence

- Port Handling Facility

- Process Area Application

- Process Area Application

- Quarry Hopper

- Quarry Hopper

- Quarry Hopper

- Stockpile Application

- Stockpile Wind Fence

- Wind Fence

- Wind Fence Installation

- Wind Fence Port Facility

- Wood Waste

- Wood Waste Dump Pocket

- GIIC-Bahrain

Portable Welding Jobsite Wind Screens

- Portable Welding Screen

- Welding Screen Stand

- Wind Fabric